Automation Engineering

pAutomation Framework

Details that make the difference!

Experience from over 25 years of electrical automation, intelligently combined with

modern methods of engineering - our pAutomation Framework.

- well thought-out and coordinated automation concept

- standardized foundation for more efficient operation

- virtual commissioning of machines and systems

- extensive testing of material flow and storage strategies thanks to real-time simulation on the digital twin

- shortened commissioning times and modernizations without significant system downtime and production losses

Our well thought-out and coordinated pAutomation Framework - based on a standardized foundation - enables economical project handling even in times of increasing complexity and is therefore ideally suited for Industry 4.0.

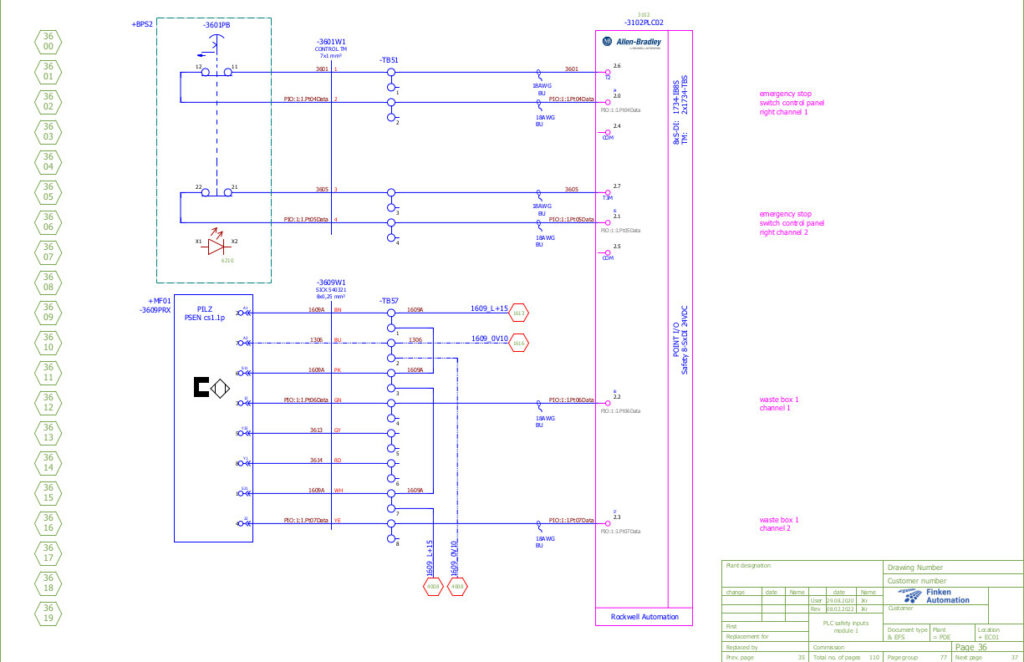

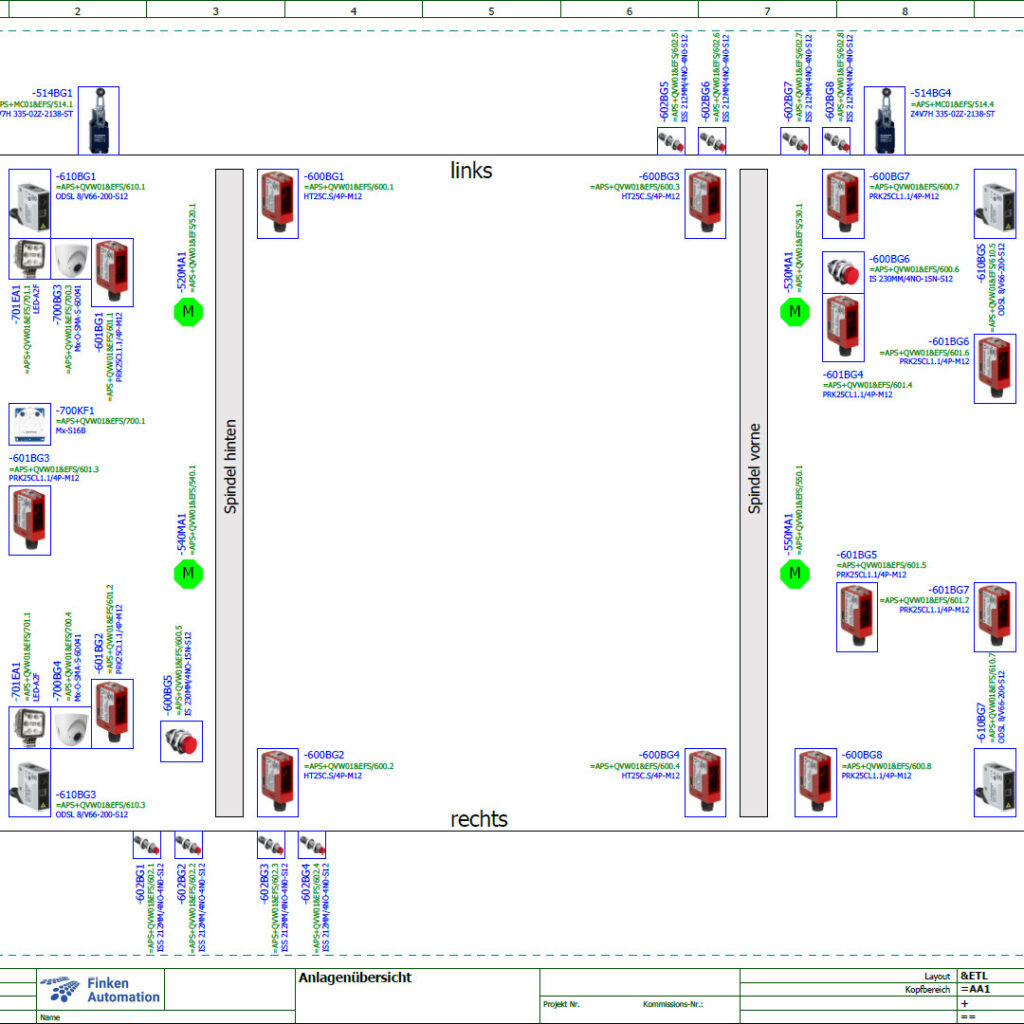

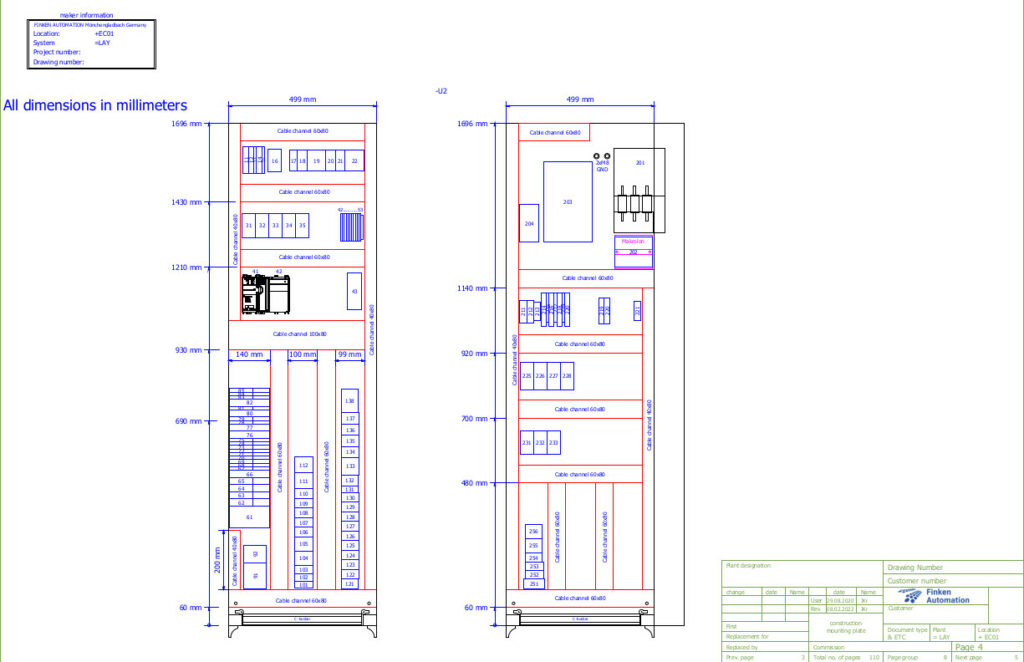

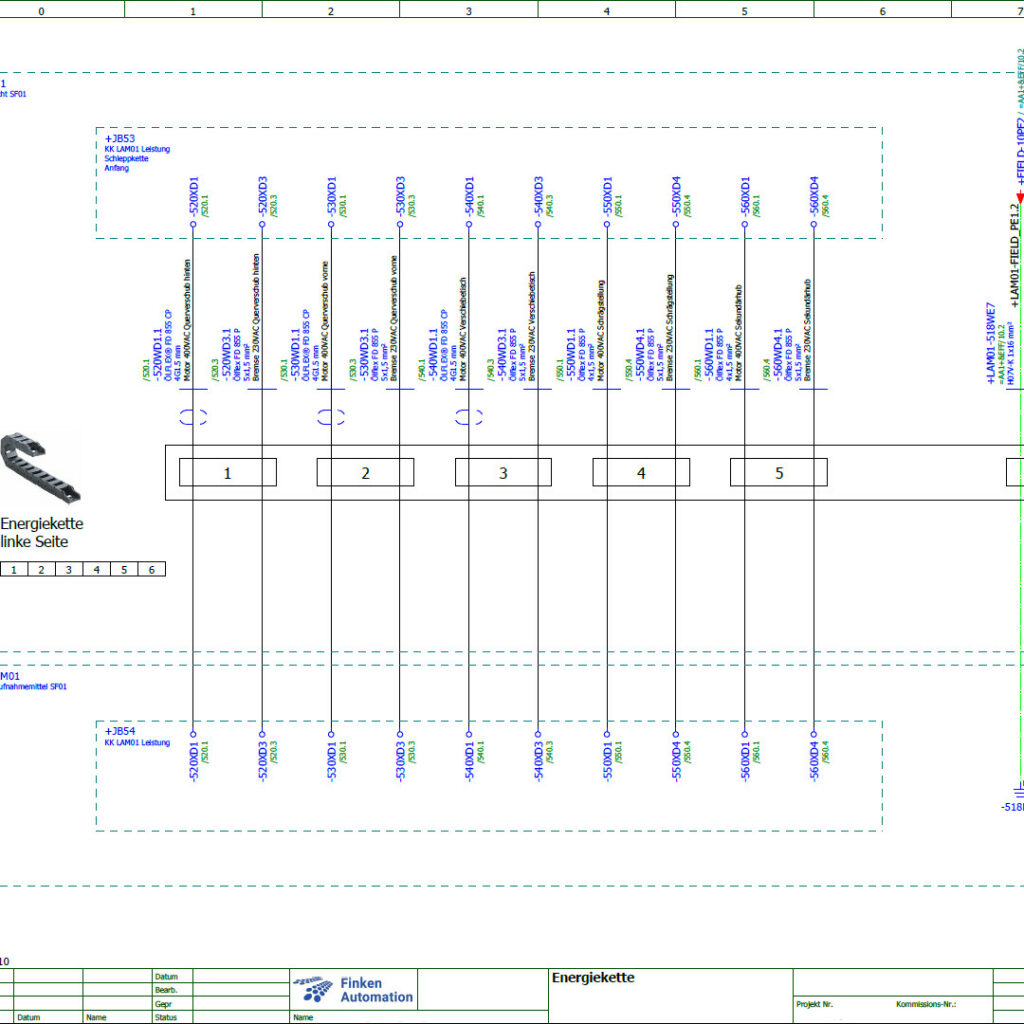

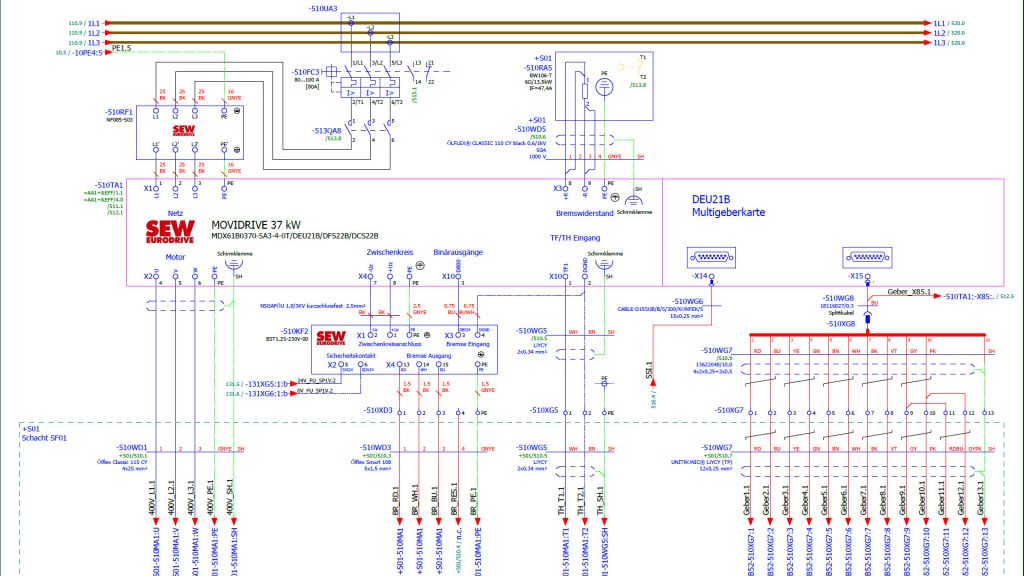

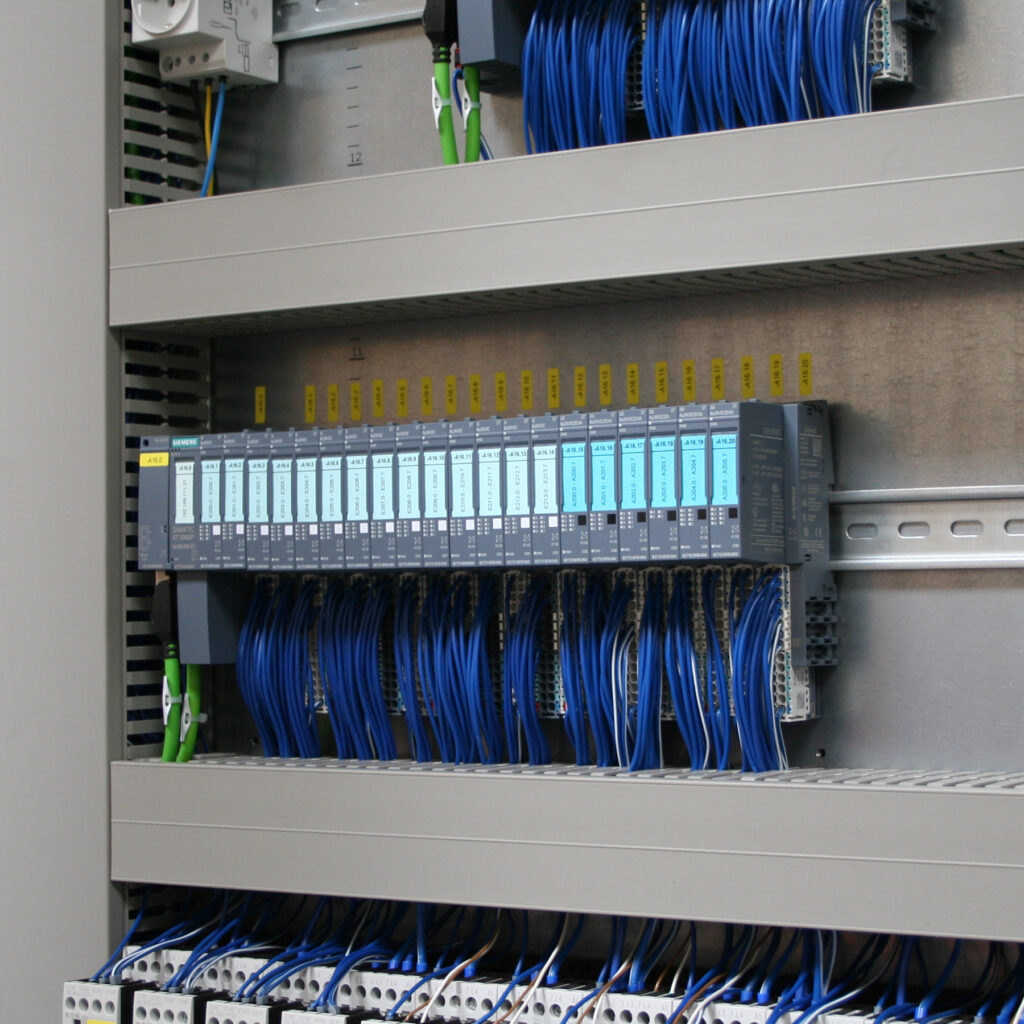

pSchematics

Our well thought-out electrical pSchematics standard serves as the basis for project planning with EPLAN P8, den The switch cabinet construction and the electrical installation. No matter whether for the European or North American market - CE and UL/CSA are already taken into account.

- we can alreday start building the switch cabinet while the electrical engineering is still being planned

- high quality standard due to standardized components

- simple electrical installation thanks to well thought-out concept

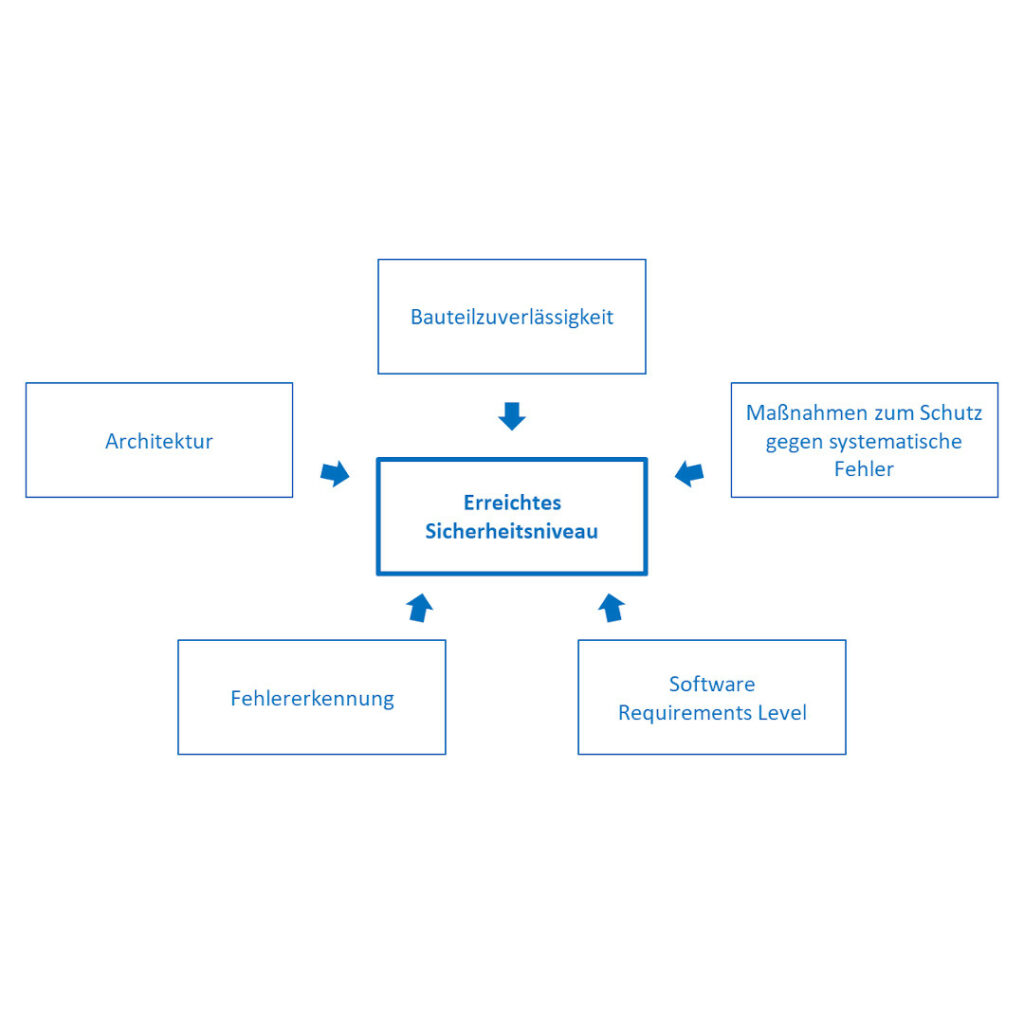

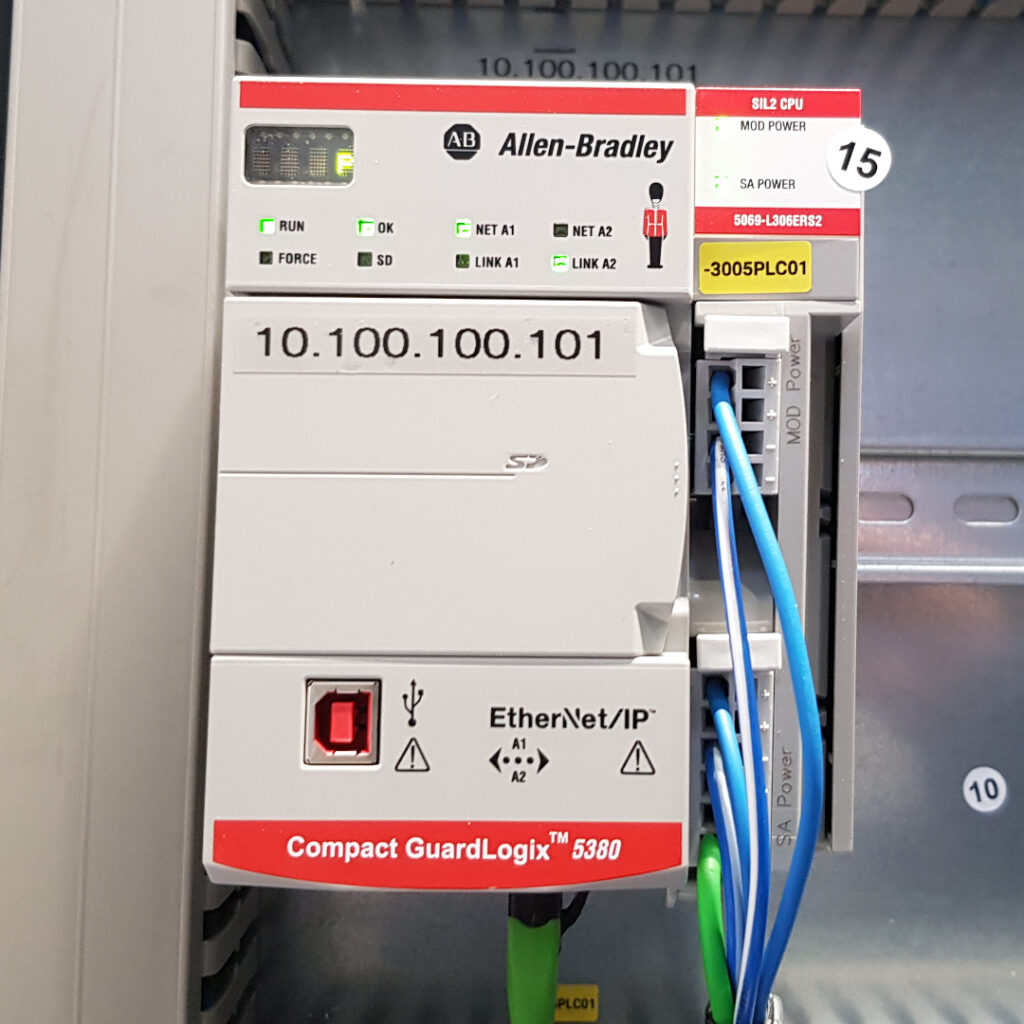

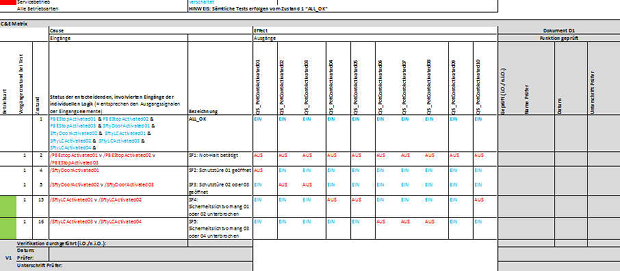

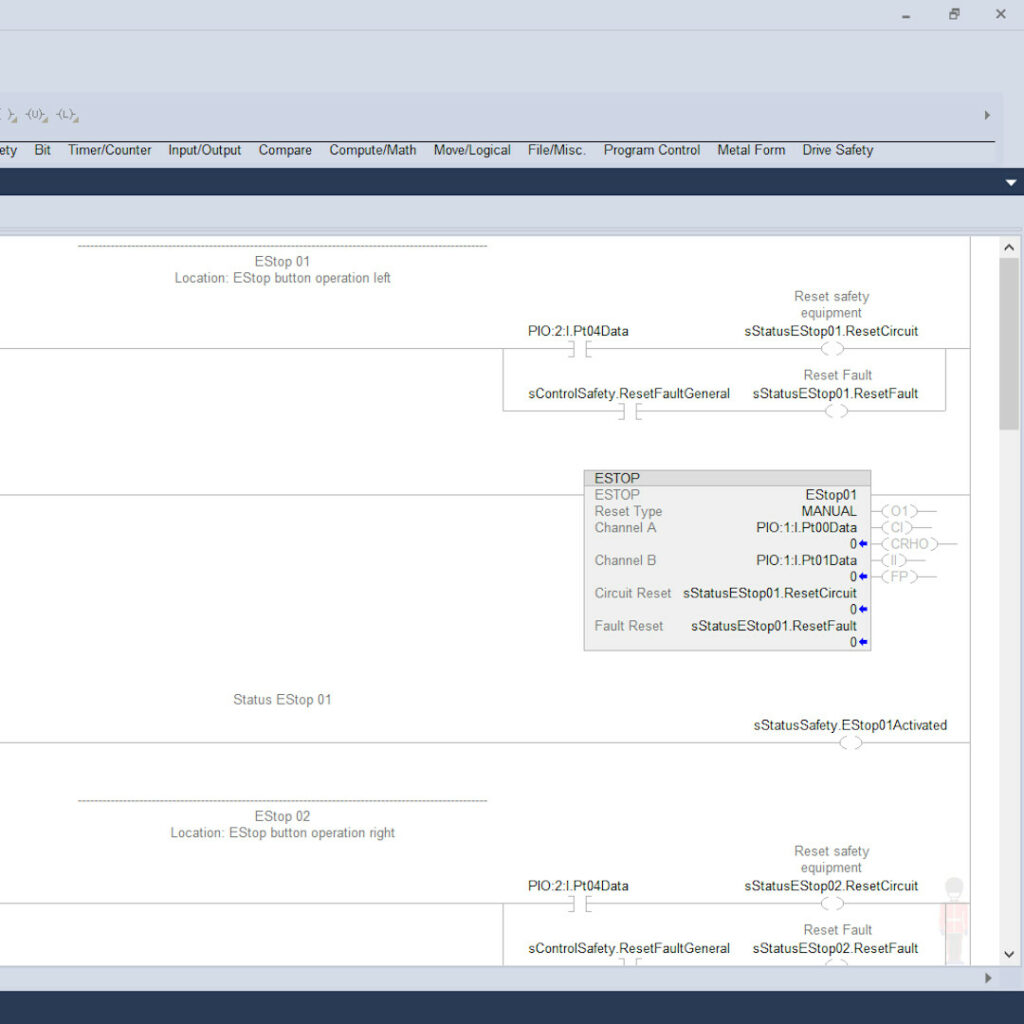

pSafety

Based on valid standards and guidelines and developed with proven engineering practice, our pSafety standard ensures first-class Machine Safety. The strictest quality controls apply throughout the entire process, from the specification of the safety functions through the implementation to the validation plan.

- TÜV (Technical Inspection Association) certified experts

- up-to-date safety standards

- as retrofit for existing plants

- for Siemens and Allen-Bradley

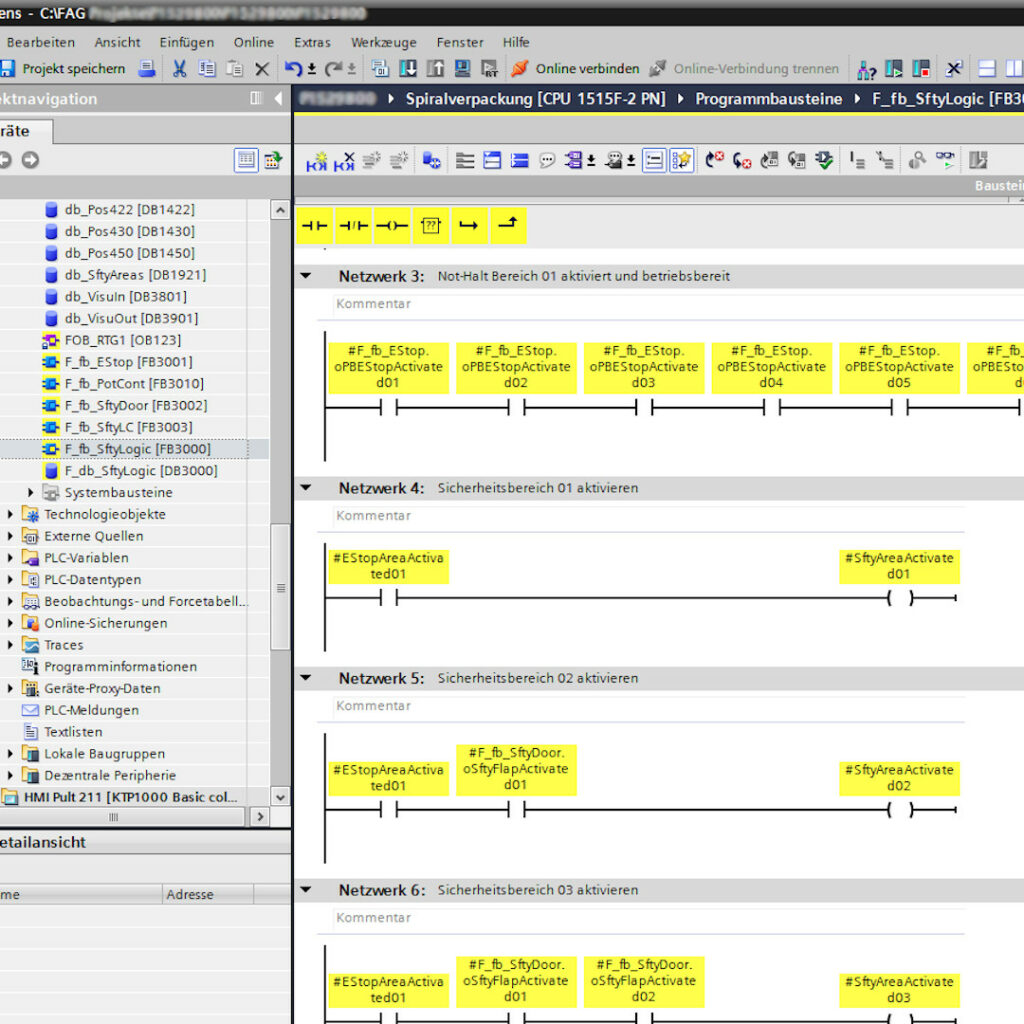

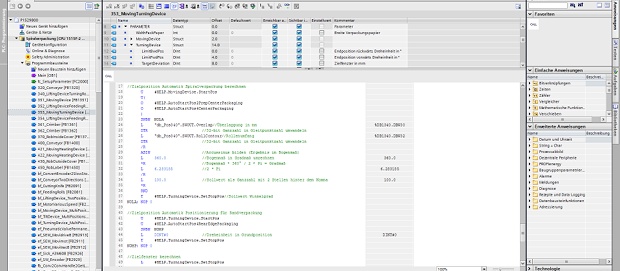

pControl

The pControl software product line combines our experience from over 25 years PLC programming with modern methods of software engineering. Furthermore, it can be used in any industry and is available for Siemens S7 as well as for Allen-Bradley controllers.

- for Siemens and Allen-Bradley the same logic

- software components proven in practice

- the same program structure for each machine

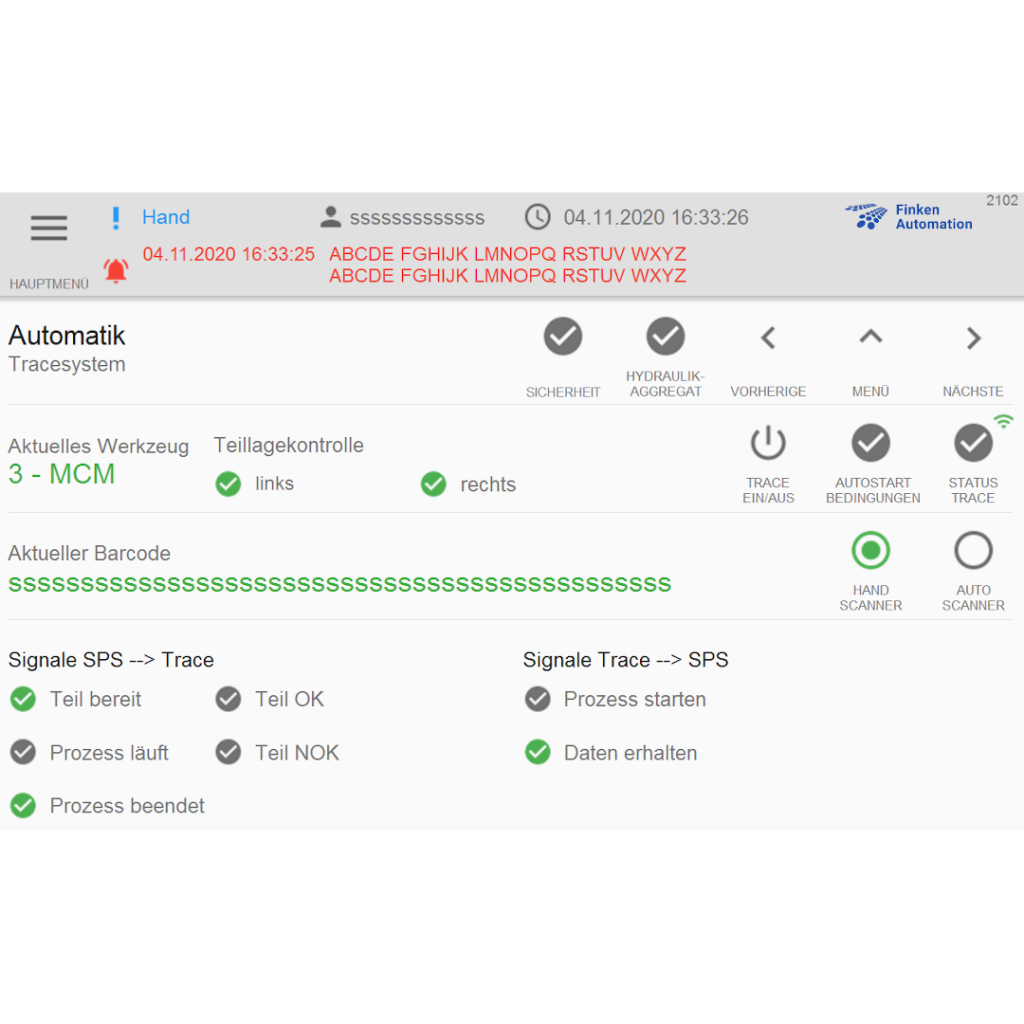

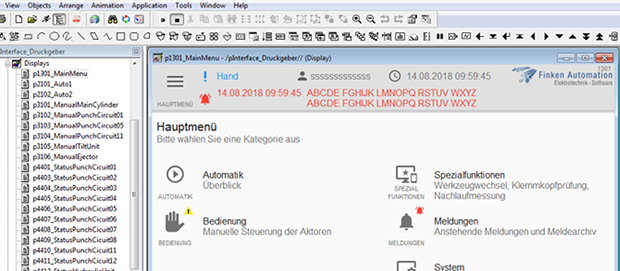

pInterface

Our intuitive and multilingual user interface pInterface provides the operating service team with all relevant information. Even with different machine types and technologies (Siemens, Allen-Bradley), the clear design is retained, thus reducing operating errors.

- the same user interface for Siemens and Allen-Bradley

- the same operating concept for every machine and system

pSimulation

With our pSimulation software module - a firmly integrated component of our pControl PLC software - we are able to commission complete systems virtually. Here, the real PLC software will pass through, which considerably reduces the effort required for commissioning the real systems. In addition, thanks to an integrated real-time simulation, all material flow and warehouse strategies can be tested in advance on the digital twin.

- virtual Commissioning of the complete system

- testing material flow and storage strategies thanks to real-time simulation on the digital twin

- significantly less effort during commissioning of the real system

- modernizations are possible without significant loss of production

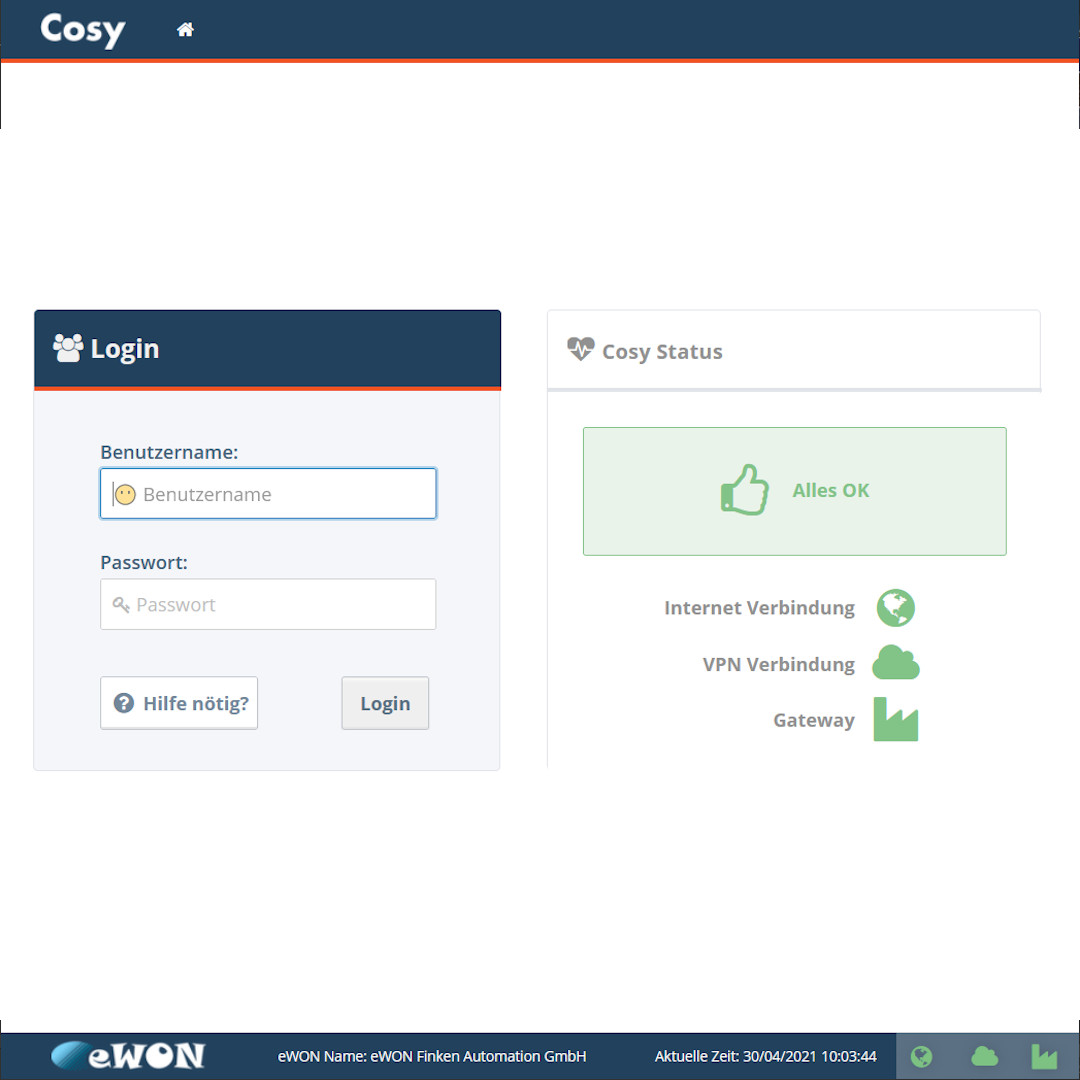

pRemote

With our pRemote standard, we provide our customers with a secure remote maintenance solution. After activation by the customer, a protected VPN connection is established which enables our service technicians to execute a fault analysis. In addition, integrated cameras can provide the option of obtaining live images of the system.

- ISO 27001 certified solution

- worldwide use

- Via cable, WLAN or mobile communications

- simple integration, even into existing systems

- live images through integrated cameras